The performance of rotary positive displacement machines highly depends on the operational clearances. It is widely believed that computational fluid dynamics (CFD) can help understanding internal leakage flows.

Developments of grid generating tools for analysis of leakage flows by CFD in rotary positive displacement machines have not yet been fully validated. Roots blower is a good representative of positive displacement machines and as such is convenient for optical access in order to analyse internal flows. The experimental investigation of flow in optical roots blower by phase-locked PIV (Particle Image Velocimetry) performed in the Centre for Compressor Technology at City, University of London provided the velocity field suitable for validation of the simulation model. This paper shows the results of the three-dimensional CFD transient simulation model of a Roots blower with the dynamic numerical grids generated by SCORG and flow solution solved in ANSYS CFX flow solver to obtain internal flow patterns. The velocity fields obtained by simulation agree qualitatively with the experimental results and show the correct main flow features in the working chamber. There are some differences in the velocity magnitude and vortex distribution. The flow field in roots blower is highly turbulent and three-dimensional. The axial clearances should be included, and the axial grids should be refined in the simulation method. The paper outlines some directions for future simulation and experimental work. The work described in this paper is a part of the large project set to evaluate characteristics of the internal flow in rotary positive displacement machines and to characterize leakage flows.

Rotary positive displacement machines are widely used in many industrial fields. Depending on the application they may contain one or more rotating elements and a stator. Typical representatives of a single rotor machine are progressive cavity pumps and single screw compressors. Twin rotor machines are more common. These can be designed either with straight lobes as in roots blowers and gear pumps, or with helical lobes used in screw compressors, expanders and pumps. Screw machines can handle single phase fluids in the form of a gas, vapour or liquid or multi-phase fluids mixed from any combination of single phase fluids and solids and may operate above or under atmospheric pressures. Liquid and multiphase pumps are often configured with multiple rotors. In all these machines, gaps between rotating and stationary parts have to be maintained in order to allow a safe and reliable operation but are desired to be minimal in order to reduce leakage flows, which play critical role in theperim

performance. The challenge is to maintain the size of the gaps due to deformations of the machine elements which could be caused by thermal of physical loads.

Many researchers have studied leakage flows through clearance gaps in rotary positive displacement machines both experimentally and numerically. Numerical methods are mostly based either on chamber modelling [1], or computational fluid dynamics (CFD) model [2, 3]. In chamber models, it is usually assumed that the momentum change in the main domain is negligible due to the internal energy being dominant while the velocity of the leaking fluid is obtained based on the assumption of the isentropic flow through the nozzle. A CFD model allows more accurate calculation of velocities both in the main domain and in the leakage paths by numerically solving governing conservation equations such as mass, energy and momentum. This is of course subject to availability of an accurate numerical mesh which can capture both, the main flow domain and clearances. The latest developments in grid generation for screw machines described in detail in Rane et al. [4, 5] have led to the mesh which can be used in all flow calculations and for most rotary positive displacement machines. This grid generation methods allows use of any commercially available CFD solvers. The size of the mesh, the speed of its generation as well as the speed of calculation by commercial solvers is suitable for industrial application. However, it is yet not fully validated if it sufficiently accurately captures flow in clearances.

Numerical procedures for calculation of performance using either chamber models or 3D CFD are usually validated by measurements of the integral parameters such as the total mass flow rate and power as shown in recent studies by Kovacevic and Rane [6]. These indicate that the clearance flow is mostly well captured. However, unless the local velocities are measured, the leakage models cannot be fully validated. In addition, even the velocity distribution in the main flow of a rotary positive displacement machine has not been studied in detail experimentally. Therefore, for the full validation of numerical calculations it is required to obtain accurate measurements of the flow field both in the main working domain and in the clearance gaps of a rotary positive displacement machine.

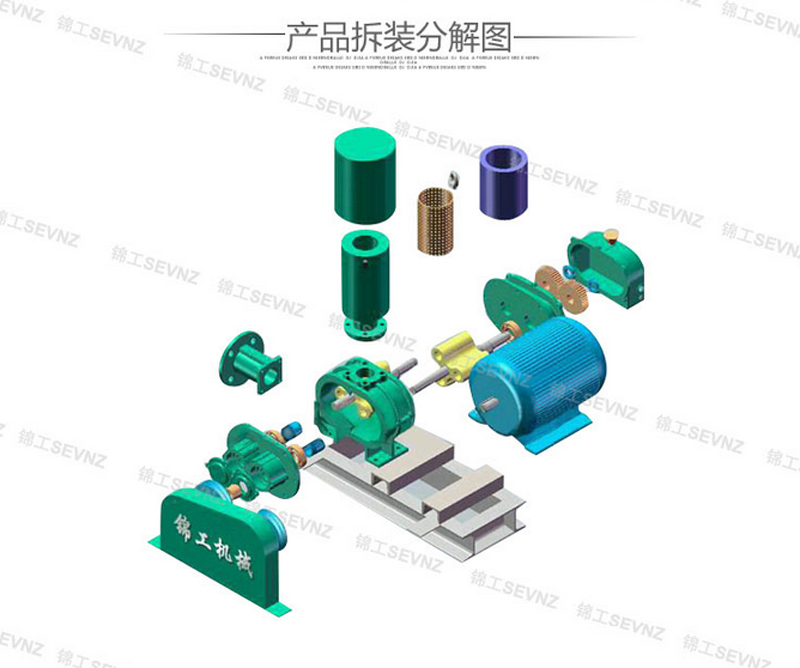

山东锦工有限公司

地址:山东省章丘市经济开发区

电话:0531-83825699

传真:0531-83211205

24小时销售服务电话:15066131928